From a simple DVD player or printer in your home to a highly sophisticated CNC machine or Robotic Arm, Stepper motors are to be found almost everywhere. Its ability to make electronically controlled precise movements have made these motors find application in many felids like surveillance cameras, Hard disk, CNC machines, 3D Printers, Robotics, Assembly robots, Laser cutters and much more.

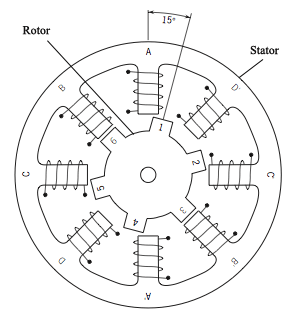

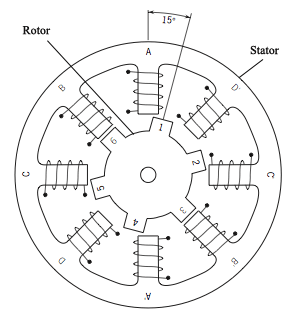

Like all motors the stepper motors also have a stator and a rotor, but unlike a normal DC motor the stator consists of individual sets of coils. The number of coils will differ based on type of stepper motor, but for now just understand that in a stepper motor the rotor consists of metal poles and each pole will be attracted by a set of coil in the stator. The below diagram shows a stepper motor with 8 stator poles and 6 rotor poles.

If you take a look at the coils on the stator, they are arranged in terms of coil pairs, like A and A’ forms a pair B and B’ forms a pair and so on. So each of this coil pair’s form an electromagnet and they can be energised individually using a driver circuitry. When a coil gets energised it acts as a magnet and the rotor pole gets aligned to it, when the rotor rotates to adjust itself to align with the stator it is called as one step. Similarly by energising the coils in a sequence we can rotate the motor in small steps to make a complete rotation.

|

| Image Source: Components101 |

Like all motors the stepper motors also have a stator and a rotor, but unlike a normal DC motor the stator consists of individual sets of coils. The number of coils will differ based on type of stepper motor, but for now just understand that in a stepper motor the rotor consists of metal poles and each pole will be attracted by a set of coil in the stator. The below diagram shows a stepper motor with 8 stator poles and 6 rotor poles.

If you take a look at the coils on the stator, they are arranged in terms of coil pairs, like A and A’ forms a pair B and B’ forms a pair and so on. So each of this coil pair’s form an electromagnet and they can be energised individually using a driver circuitry. When a coil gets energised it acts as a magnet and the rotor pole gets aligned to it, when the rotor rotates to adjust itself to align with the stator it is called as one step. Similarly by energising the coils in a sequence we can rotate the motor in small steps to make a complete rotation.